Cold supply for hot demand

Transforming the market for cold chain equipment in the world’s poorest countries.

- 8 April 2018

- 11 min read

Cold chains have facilitated the delivery of vaccines in some of the world's poorest countries for over 40 years. Today, they are increasingly outdated and struggle to handle a rising number of vaccines.

Modern technology has the potential to transform cold chains, but purchase and maintenance costs can be too high for the world’s poorest countries.

Shaping markets is one of the success stories of Gavi's public-private model. After transforming vaccine markets, the Alliance is applying the same approach to cold chain equipment.

Haiti

In Haiti, 65-year-old Joseph Mesura shoulders a nine-kilogramme propane cylinder. For six hours he carries this burden across rough fields, rivers and up rocky slopes until he reaches the rural village of Taifer in the mountains behind Port-au-Prince. Each month, Joseph makes the same hot, tiring journey, which he calls “a mission of God”. He has little choice.

In Haiti, 65-year-old Joseph Mesura shoulders a nine-kilogramme propane cylinder. For six hours he carries this burden across rough fields, rivers and up rocky slopes until he reaches the rural village of Taifer in the mountains behind Port-au-Prince. Each month, Joseph makes the same hot, tiring journey, which he calls “a mission of God”. He has little choice.

Haiti is among the poorest countries in the world, destabilised in recent years by political turmoil and natural disaster. Up in the mountains, there is no mains electricity. He is delivering the gas to a health clinic. Without the gas cylinders, the clinic cannot power a fridge that maintains vaccines at their prescribed temperature. If Joseph doesn’t make it, local children can’t be immunised against life-threatening illnesses.

Haiti is among the poorest countries in the world, destabilised in recent years by political turmoil and natural disaster. Up in the mountains, there is no mains electricity. He is delivering the gas to a health clinic. Without the gas cylinders, the clinic cannot power a fridge that maintains vaccines at their prescribed temperature. If Joseph doesn’t make it, local children can’t be immunised against life-threatening illnesses.

Lao People's Democratic Republic

Across the world, in Lao People’s Democratic Republic (Lao PDR), things are different. In the rural village of Kaengkhane, a two and half hour’s boat journey from the city of Luang Prabang, the government has recently built a new health centre. It is wired to the national electricity grid. It has solar panels that provide back-up power should the mains grid fail. On a shiny floor, surrounded by gleaming white walls, sits a large modern fridge designed to keep vaccines cool, and potent.

Different, but not much better

More than a month ago, an electrical storm caused a surge of power that broke the fridge. It hadn’t been protected by an electrical stabiliser. The solar panels aren’t working, and no-one living nearby has the technical skills or spare parts to fix either. So the fridge sits empty, after health workers hurriedly moved the vaccines into small cool boxes, which they must continually pack with ice. It’s the only way to prevent the vaccines being corrupted by the heat.

Gavi model in action: Immunisation cold chain

The clinic in Haiti lacks modern refrigeration technology, jeopardising its immunisation efforts. In Lao PDR, the clinic lacks access to the parts and technicians required to maintain their modern fridges, placing their immunisation programme at risk.

Similar stories can be told around the developing world. The network of fridges, cool boxes and sensors used to store and transport vaccines, keeping them at optimal temperatures, is known as the cold chain. Unless poorer countries can afford to purchase and maintain cold chain equipment, they risk the lives of their people.

It’s not only a question of modernising and servicing existing cold chains. Innovative technology is also key to extending the cold chain to remote communities that are currently off the electricity grid, ensuring life-saving vaccines can reach everybody.

The Vaccine Alliance is working on many fronts to remove this inequity. A key element of this is building sustainable markets for cold chain equipment in developing countries. Through its cold chain equipment optimisation platform (CCEOP), a grant launched in 2016, Gavi encourages companies to design more cost-effective, efficient and better performing cold chain equipment which it jointly finances with countries. The grant covers the cost of the equipment, delivering and installing it on site, and its maintenance, including the training of technicians, spare parts and warranties.

These efforts are especially important in the world's poorest countries, where markets for new technologies rarely exist. On the supply side, companies have no guarantee they can sell innovative cold chain equipment to developing countries. On the demand side, many governments cannot afford to access the technologies needed to keep their vaccines safe and effective. The absence of a viable market leads to a lack of functioning, reliable cold chain equipment, often with devastating consequences.

Ensuring strong, sustainable vaccine cold chains is not just about buying new equipment. It requires a holistic, market-based approach addressing issues on both supply and demand side.

Too hot, too cold

Vaccines are biological products that can lose their effectiveness if they are not kept within a narrow temperature range. Most are heat sensitive: warm temperatures kill the live-attenuated viruses or bacteria within, reducing potency. Many are also freeze-sensitive: extreme cold can corrupt adjuvants added to vaccines to help them work, reducing their effectiveness.

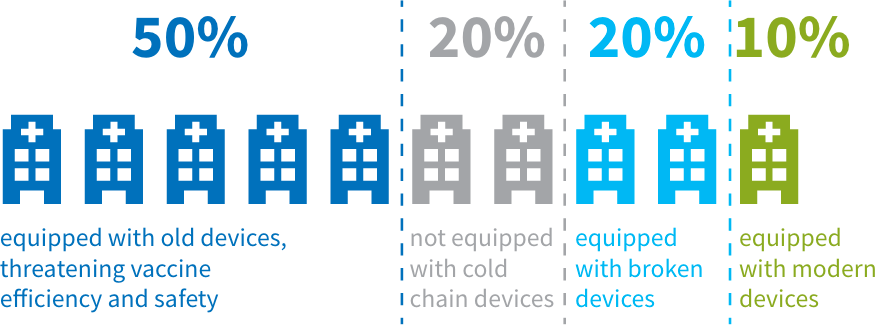

The challenge: up to 90% of medical facilities lack modern equipment

However, around one fifth of immunisation facilities in the world’s poorest countries don’t have the equipment needed to keep vaccines at optimal temperatures. Of those that do, much functions poorly or doesn’t work at all. Or the equipment is not optimised to protect modern vaccines, which must be more precisely stored and more accurately monitored. That undermines immunisation efforts.

A 2017 review of the extent of freeze damage found that between 37-50% of all monitored vaccines stored in lower-income countries had at some point been stored at temperatures deemed "too cold".

A series of natural disasters have only exacerbated the precarious state of the cold chain. In 2010, a catastrophic earthquake killed more than 230,000 people on the Caribbean island, fracturing the nation’s public health system and fragile national grid. Today, only half the population have access to healthcare services.

The impact on immunisation coverage and health is clear and present. According to WHO and UNICEF estimates, by 2016 Haiti had 58% coverage for the third dose of diphtheria-tetanus-pertussis vaccine – the lowest rate in the Americas. An estimated 50 children die from vaccine-preventable disease each day.

A series of natural disasters have only exacerbated the precarious state of the cold chain. In 2010, a catastrophic earthquake killed more than 230,000 people on the Caribbean island, fracturing the nation’s public health system and fragile national grid. Today, only half the population have access to healthcare services.

The impact on immunisation coverage and health is clear and present. According to WHO and UNICEF estimates, by 2016 Haiti had 58% coverage for the third dose of diphtheria-tetanus-pertussis vaccine – the lowest rate in the Americas. An estimated 50 children die from vaccine-preventable disease each day.

Investing in cold chain equipment

Like many poor countries, Haiti has historically struggled to make the upfront investment required to purchase new cold chain equipment. It also lacked the finances, and technological expertise needed to maintain it. Not surprisingly, few manufacturers saw Haiti as a viable market for hi-tech equipment.

The CCEOP was set up to address exactly this problem. From 2016 to 2017, the Vaccine Alliance committed US$ 50 million to modernise cold chain equipment in the world’s poorest countries. Over the next five years, this initial investment will be increased five-fold to match the anticipated demand.

The upfront commitment gives manufacturers confidence to produce innovative cold chain equipment adapted to the needs of developing countries. By helping countries purchase and maintain this equipment, Gavi removes one of the main barriers standing in the way of cold chain modernisation.

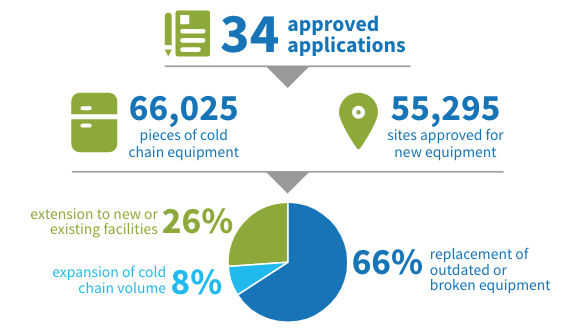

To date, Gavi has agreed to support the purchasing of more than 65,000 pieces of cold chain equipment for more than 55,000 different sites used to store or transport vaccines. Two thirds will replace outdated or broken equipment, while the rest will help extend cold chain facilities and their output.

The Haitian Health Ministry, supported by Alliance partners, was the first country to take advantage of the CCEOP to overhaul its outdated cold chain. In 2017, a first consignment of over 191 state-of–the-art solar-powered fridges was deployed to rural and mountainous areas.

Like many poor countries, Haiti has historically struggled to make the upfront investment required to purchase new cold chain equipment. It also lacked the finances, and technological expertise needed to maintain it. Not surprisingly, few manufacturers saw Haiti as a viable market for hi-tech equipment.

The CCEOP was set up to address exactly this problem. From 2016 to 2017, the Vaccine Alliance committed US$ 50 million to modernise cold chain equipment in the world’s poorest countries. Over the next five years, this initial investment will be increased five-fold to match the anticipated demand.

The upfront commitment gives manufacturers confidence to produce innovative cold chain equipment adapted to the needs of developing countries. By helping countries purchase and maintain this equipment, Gavi removes one of the main barriers standing in the way of cold chain modernisation.

To date, Gavi has agreed to support the purchasing of more than 65,000 pieces of cold chain equipment for more than 55,000 different sites used to store or transport vaccines. Two thirds will replace outdated or broken equipment, while the rest will help extend cold chain facilities and their output.

The Haitian Health Ministry, supported by Alliance partners, was the first country to take advantage of the CCEOP to overhaul its outdated cold chain. In 2017, a first consignment of over 191 state-of–the-art solar-powered fridges was deployed to rural and mountainous areas.

“We are installing some of these fridges in mountainous areas that are really difficult to access - the kind of places where it’s hard to carry a propane bottle. They will make a big difference to remote communities that were beyond the reach of gas-powered fridges.”

Connected to solar panels, the new fridges are powered by renewable energy. During the day, an ice liner is frozen that can keep the unit cold overnight or during cloudy days. With no need for a battery and control unit, they are not reliant on the kind of components that are prone to failing on older fridge models.

Installation in Haiti should be completed by 2020, eliminating the need for Joseph Mesura to carry propane bottles 16 km up mountain slopes.

Gavi’s cold chain equipment optimisation platform: results

Connected to solar panels, the new fridges are powered by renewable energy. During the day, an ice liner is frozen that can keep the unit cold overnight or during cloudy days. With no need for a battery and control unit, they are not reliant on the kind of components that are prone to failing on older fridge models.

Installation in Haiti should be completed by 2020, eliminating the need for Joseph Mesura to carry propane bottles 16 km up mountain slopes.

Gavi’s cold chain equipment optimisation platform: results

Gavi model in action: cold chain equipment optimisation platform

CCEOP highlights Gavi’s ability to adopt market-based approaches thanks to its public-private partnership model, which brings together all key stakeholders in immunisation. Since the Alliance’s foundation in 2000, the same innovative approach has successfully transformed several vaccine markets, ensuring the right products are available in adequate supply and at affordable prices for the world’s poorest countries. Now, Gavi’s business model is set to transform both sides of the cold chain market.

Most Gavi-supported countries are able to apply for support through the CCEOP. Based on each country’s Gross National Income per capita, Gavi will cover 50-80% of the total purchase, delivery and installation costs. The country itself is expected to fund the remaining cost. CCEOP aims to encourage an increase in the number of manufacturers supplying innovative equipment for the cold chain.

So far, Gavi has committed to helping countries purchase 66,000 cold chain equipment items, including solar direct drive fridges, through the CCEOP.

The experience of the village of Kaengkhane in Lao PDR demonstrates that the cold chain is only as strong as its weakest links. While solar-powered fridges are more efficient and cost-effective than traditional fridges, spare parts and skilled technicians and funding to pay for them are required to ensure long-term maintenance. In Kaengkhane, these are in short supply.

While Lao PDR has yet to apply for CCEOP support, it plans to do so in the near future.

CCEOP highlights Gavi’s ability to adopt market-based approaches thanks to its public-private partnership model, which brings together all key stakeholders in immunisation. Since the Alliance’s foundation in 2000, the same innovative approach has successfully transformed several vaccine markets, ensuring the right products are available in adequate supply and at affordable prices for the world’s poorest countries. Now, Gavi’s business model is set to transform both sides of the cold chain market.

Most Gavi-supported countries are able to apply for support through the CCEOP. Based on each country’s Gross National Income per capita, Gavi will cover 50-80% of the total purchase, delivery and installation costs. The country itself is expected to fund the remaining cost. CCEOP aims to encourage an increase in the number of manufacturers supplying innovative equipment for the cold chain.

So far, Gavi has committed to helping countries purchase 66,000 cold chain equipment items, including solar direct drive fridges, through the CCEOP.

The experience of the village of Kaengkhane in Lao PDR demonstrates that the cold chain is only as strong as its weakest links. While solar-powered fridges are more efficient and cost-effective than traditional fridges, spare parts and skilled technicians and funding to pay for them are required to ensure long-term maintenance. In Kaengkhane, these are in short supply.

While Lao PDR has yet to apply for CCEOP support, it plans to do so in the near future.

Gavi model in action: INFUSE

CCEOP is not the only market-based approach that Gavi uses to give countries access to innovative solutions to ensure vaccines safely reach their destination. Launched in 2016, Innovation for Uptake, Scale and Equity in Immunisation (INFUSE) identifies tried and tested private-sector initiatives with the potential to improve vaccine delivery. It then “infuses” them with capital and expertise to ensure developing countries can introduce them.

CCEOP is not the only market-based approach that Gavi uses to give countries access to innovative solutions to ensure vaccines safely reach their destination. Launched in 2016, Innovation for Uptake, Scale and Equity in Immunisation (INFUSE) identifies tried and tested private-sector initiatives with the potential to improve vaccine delivery. It then “infuses” them with capital and expertise to ensure developing countries can introduce them.

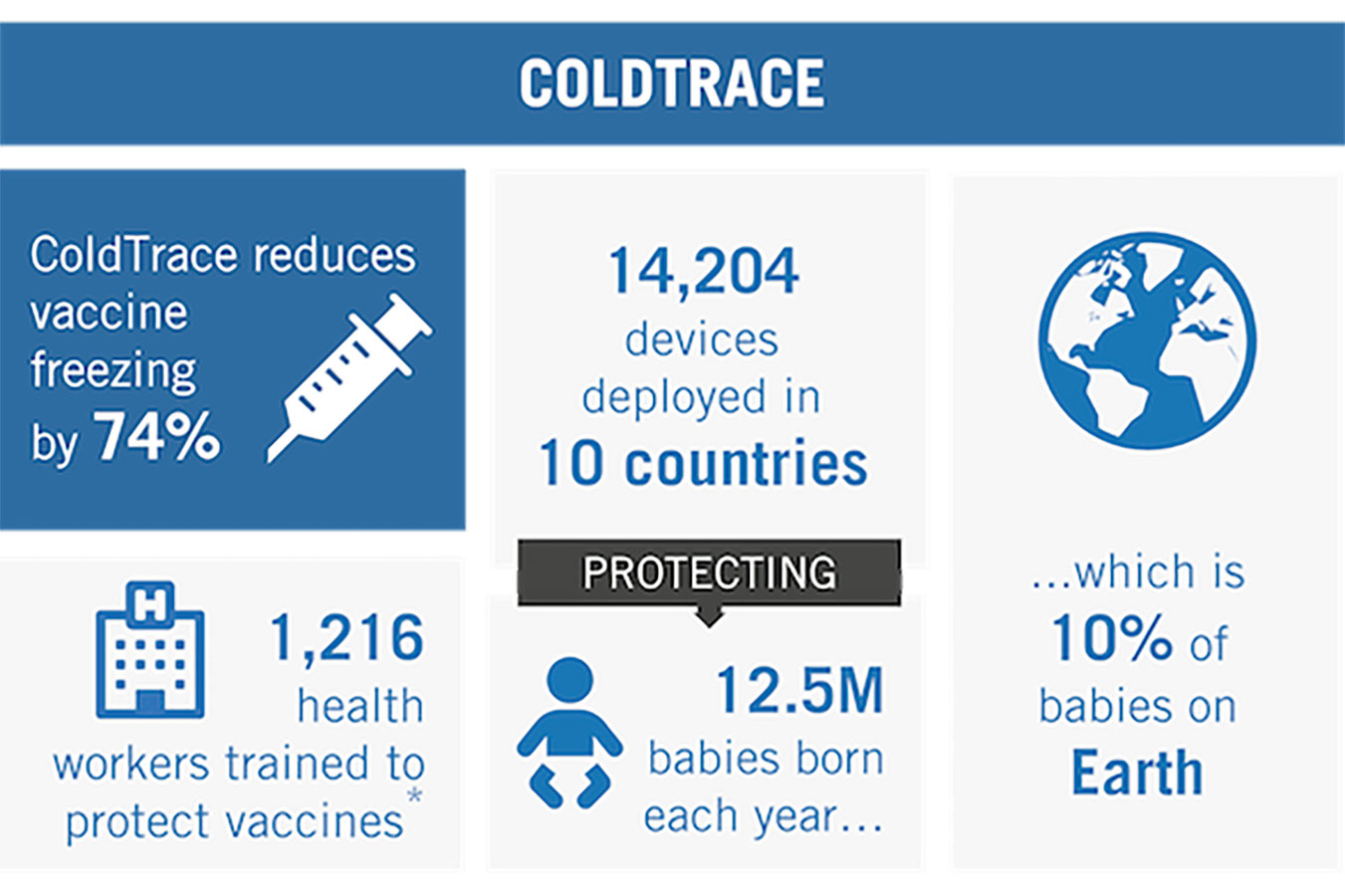

In January 2017, Gavi and Google.org announced an INFUSE partnership to help tech start-up Nexleaf Analytics develop a cloud-based analytics platform which monitors cold chain performance in real-time. The platform will use Nexleaf’s ColdTrace technology in combination with other temperature monitors.

After initial introductions in Tanzania, Kenya, Mozambique, and Senegal, it is hoped that this innovation will eventually help all Gavi-supported countries to manage their networks of cold chain fridges with greater speed and precision. Additional support from ELMA Vaccines and Immunisations Foundation will help scale-up the project in Tanzania in 2018.

“Cold Trace offers real-time temperature data, and other information about vaccines – both when they are transported and stored,” says Nexleaf CEO and co-founder Nithya Ramanathan. “The solution is also about how data is brought to an entire Ministry of Health, from the health worker to central government. To date, we’ve been able to scale-up our technologies in four different countries.”

Energize the Chain

INFUSE is also supporting a range of other technologies that underline the many ways in which private sector innovation can strengthen the vaccine delivery system.

One of the first cold chain innovations to benefit from INFUSE was Energize the Chain, which uses mobile phone masts to power the cold chain in areas off the national power grid.

Mobile phone masts are often the only infrastructure to reach remote rural areas of sub-Saharan Africa, where almost 600 million people lack access to electricity. Each mast is typically powered by 5 to 10kWh of excess electricity daily. Energize the Chain recognised the potential for leveraging this extra power to keep vaccine storage boxes, fridges and freezers cold.

The company is already working with African health ministries and partners on the ground to deploy refrigerators that work in this way. Energize the Chain also provides nearby clinics with vaccine boxes containing cold packs so vaccines can be safely transported to vaccination sessions.

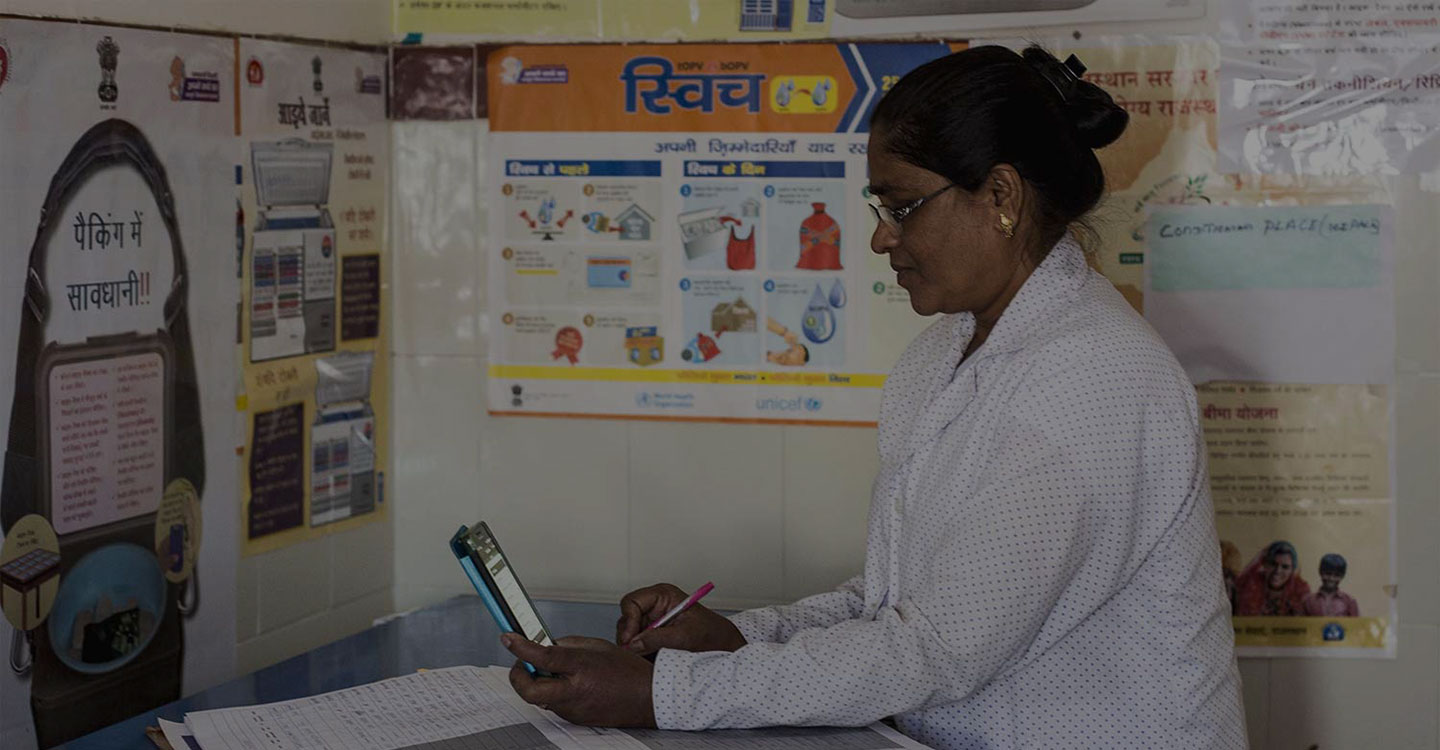

Monitoring vaccines in India

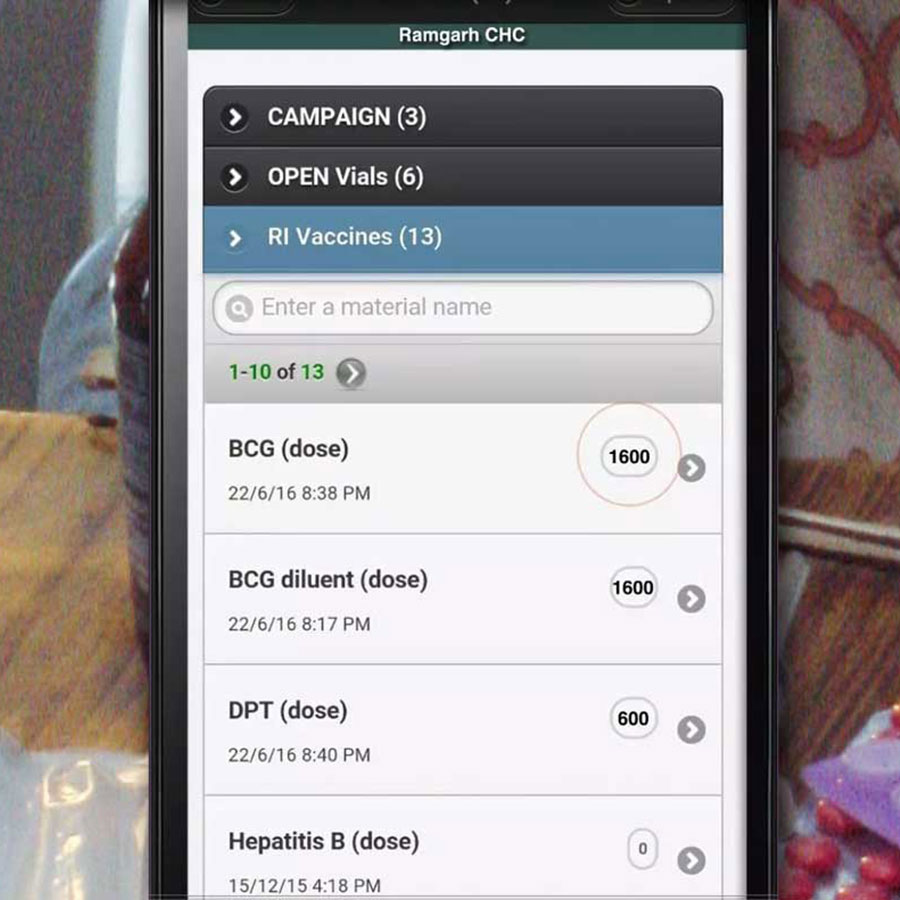

New technology is playing a critical role in monitoring one of the world’s most extensive cold chains. With more than 300 million vaccine doses to administer each year, India has struggled to monitor its stocks.

Now, the Electronic Vaccine Intelligence Network (eVIN), introduced by the Government and the UN Development Programme with Gavi support, is helping monitor the vast national network of 27,000 cold chain points. Public health officials use a mobile phone app to track the temperatures of cold chain equipment in real time, as recorded by tens of thousands of temperature sensors. The system also allows more than two million vaccine transactions to be logged, and inventories audited.

New technology is playing a critical role in monitoring one of the world’s most extensive cold chains. With more than 300 million vaccine doses to administer each year, India has struggled to monitor its stocks.

Now, the Electronic Vaccine Intelligence Network (eVIN), introduced by the Government and the UN Development Programme with Gavi support, is helping monitor the vast national network of 27,000 cold chain points. Public health officials use a mobile phone app to track the temperatures of cold chain equipment in real time, as recorded by tens of thousands of temperature sensors. The system also allows more than two million vaccine transactions to be logged, and inventories audited.

16-fold return on investment in immunisation

Investing in innovative cold-chain technologies pays off on many fronts. Modernising equipment and swapping to solar-powered fridges saves money: older technologies often have high operating costs and/or poor temperature control that can lead to vaccine wastage if vaccines are exposed to warm or freezing temperatures.

New equipment is not only more reliable and cost-effective, but also more environmentally friendly. Switching from old, inefficient refrigerators powered by generators and fossil-fuels, to cleaner, more renewable energy sources, such as solar power, can help prevent pollution and climate change. Gavi’s support also includes monitoring devices that ensure optimum energy usage and reduce wastage.

The installation of cold chain equipment facilitates the introduction and extension of other vital services, such as power grids and healthcare. Most importantly, optimising the cold chain means many more people can be reached with safe and effective vaccines against life-threatening diseases. When children and adults are vaccinated against disease, they are protected for years and lifetimes. This saves the significant costs and burden of treating life-threatening diseases, and allows people, and the societies and countries they live in, to thrive and prosper.

Research has shown that for every dollar invested in immunisation in the world's 94 poorest countries, there is a return on investment of US$ 16 in healthcare costs, lost wages and lost productivity due to illness. The equivalent figure for Gavi-supported countries is even higher: US$ 18 per dollar invested.

Taking into account broader benefits of people living longer, healthier lives, the return on investment reaches US$ 44 per dollar spent, rising to US$ 48 per dollar in Gavi-supported countries.

Conversely, a failure to invest in modern cold chain equipment not only jeopardises the viability of vaccines. It places the Alliance’s wider investments in immunisation at risk, undermining vaccine introductions and efforts to reach those who are missing out on life-saving vaccines.

That’s why creating markets for cold chain technology is an important thing to do. And it’s a cool thing to do.